Cómo perforar un agujero en ópalo

Perforar un ópalo no es tan sencillo como parece. Muchas personas compran ópalos u otras piedras preciosas e intentan perforarlas sin éxito. Esto puede resultar muy frustrante si no se siguen las instrucciones.

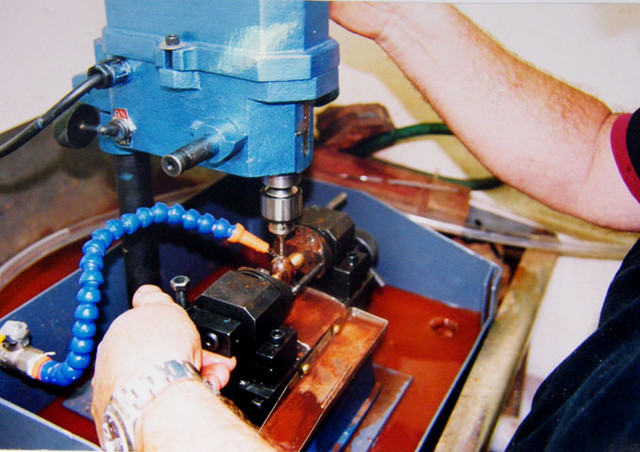

Aquí tenéis una versión casera fabricada en los campos de ópalo de Winton, Queensland, para perforar agujeros en ópalos de roca.

Es una herramienta rotativa tipo Dremel montada sobre un eje de prensa manual, lo que permite subirla o bajarla haciendo palanca. En la base, tiene un vástago ajustable para sujetar la broca inferior. Es una idea genial, ya que, como bien saben quienes intentan taladrar, es difícil conseguir que los agujeros coincidan.

Si intentas taladrar hasta el fondo, el ópalo se astillará en el extremo, por lo que este sistema es fácil de hacer en casa y consiste en taladrar agujeros en ambos extremos del ópalo para que coincidan perfectamente.

¿Qué herramientas necesito para perforar un agujero en ópalo?

Las brocas con punta de diamante son adecuadas para perforar pequeñas cantidades de ópalos. Estas brocas tienen puntas de diamante de diferentes grados y formas: redondas, puntiagudas, alargadas o huecas. El grano 120 es adecuado para perforar agujeros.

Estas brocas se pueden acoplar a cualquier taladro doméstico estándar o herramienta rotativa tipo Dremel, pero si la velocidad del taladro es alta, los diamantes se quemarán en cuestión de segundos. Esto sucede con frecuencia debido al intenso calor que se genera cuando una broca de diamante entra en contacto con la piedra, y además requiere humedad constante durante el proceso de perforación. El taladro debe funcionar a baja velocidad.

Los accesorios estándar para taladros domésticos que sujetan una broca son adecuados, pero necesitará un bloque para mantener estable el Opal durante el taladrado.

Cómo perforar un agujero en ópalo

Taladre un agujero hasta la mitad de la piedra. Para empezar, incline el taladro y, si lo usa a mano, levántelo lentamente hasta la posición vertical sin ejercer presión. Retire la broca del agujero varias veces para eliminar el material sobrante; esto permitirá que el agua lave el orificio y evitará que el taladro se sobrecaliente. No ejerza presión al taladrar.

Luego, gira la piedra y taladra desde el otro lado de manera que la unión quede en el centro del ópalo. No es fácil lograr la precisión, pero si taladras completamente el ópalo, la broca sobresaldrá por el otro lado, astillando los bordes y obteniendo un acabado deficiente.

Consejos

Existen algunas abrazaderas comerciales que pueden girar la piedra más de 180 grados.

Se pueden fabricar abrazaderas de madera, pero es importante poder voltear la piedra y taladrar un orificio exacto para lograr una unión limpia.

Algunos talladores pegan el ópalo a la mesa para que quede sólido y luego perforan el agujero.

Si su taladro no tiene control de velocidad lenta, mantenga la profundidad de perforación de manera que solo toque ligeramente la piedra.

Lo mejor es trabajar despacio y con mucha agua.

Conecta un tubo o manguera al grifo para que el flujo de agua sea constante.

Ajuste el taladro a la velocidad más lenta, entre 7000 y 10 000 rpm; esta es la configuración más lenta en los taladros Dremel.

Muchas grandes fábricas de corte cuentan con máquinas de perforación ultrasónica que realizan agujeros mediante vibraciones de alta frecuencia. Este sistema es ideal para grandes empresas, pero resulta caro, y las versiones económicas que hemos visto no ofrecen un acabado satisfactorio.

Elaboración de cuentas de ópalo

Se pueden adquirir muelas diamantadas estándar de 7,6 a 10,2 cm de ancho, curvadas para formar perlas semicirculares. La mayoría son de grano 100 a 140.

Para empezar a dar forma al ópalo, preferiblemente ópalo de roca o ópalo de hierro con vetas de color, lo mejor es darle forma rectangular. Esta forma rectangular alargada se ajusta a la rueda curva con punta de diamante mediante un accesorio que puede girar o accionarse manualmente. El resultado serán cuentas uniformes con dos bloques en cada extremo que se pueden cortar con una hoja de sierra.

Muchos talladores se decepcionan al hacer cuentas, ya que el ópalo en bruto suele ser bueno para empezar, pero la mayor parte del color desaparece al hacer cuentas, así que asegúrese de usar ópalo en bruto que tenga vetas de color, ya que normalmente producen una buena cuenta terminada.

Esta máquina cortadora de cuentas convertirá las cuentas de ópalo de roca en cuentas perfectamente redondas. Primero, la cortadora debe dar forma rectangular al ópalo para crear la cuenta. Si alguna vez has intentado cortar un ópalo en forma redonda, te darás cuenta de lo difícil que es.

Consejos

El ópalo matriz también es adecuado para hacer cuentas.

El ópalo negro rara vez se utiliza para fabricar cuentas debido al costo del ópalo en bruto.

Consejos para pulir

Las puntas de goma también son útiles para hacer agujeros o pulir superficies onduladas en ópalos.

Las puntas de goma impregnadas de diamante son ideales para rematar bordes después de perforar el agujero o cualquier superficie ondulada.

Si no tienes puntas de goma, puedes colocar papel de lija de 1 a 2 pulgadas de diámetro sobre un disco de goma flexible y usar pegamento adhesivo de contacto para que los papeles de lija se puedan cambiar fácilmente cuando se desgasten.

No requiere agua.

Es imprescindible disponer de un sistema de succión de aire para extraer el aire y usar una mascarilla siempre que se pula sin agua.

Se pueden usar aspiradoras, pero deben tener una succión potente y la mayoría de las aspiradoras domésticas no son lo suficientemente potentes como para eliminar las partículas de polvo de la cara y la boca.

Para el pulido final, puedes usar una pulidora y polvo de pulir en pasta con cabezales cóncavos y convexos. Son ideales para zonas de difícil acceso, especialmente en ópalo de roca ondulado.

Los libros sobre ópalo también son útiles para obtener consejos prácticos sobre el corte y pulido de esta piedra. Un ejemplo es «Opal & How to work it» de Frank Barnet.

Estoy segura de que estarás de acuerdo en que, después de intentar hacer algunas cuentas tú mismo, comprenderás por qué las cuentas de ópalo de buena calidad son tan caras.

COMPRA ÓPALOS

Buscar en el Opal Encyclopedia

Subastas relacionadas

Artículos relacionados

Existen numerosos yacimientos de ópalo en Queensland, distribuidos a lo largo de más de 1000 km. Haga clic para obtener más información sobre cada ubicación y ver los hermosos ópalos de Queensland que tenemos a la venta.

5th Mar 2019

La clave para lograr la cartera más efectiva posible reside en tener una cartera diversificada. Esta es la razón por la que algunos asesores financieros de renombre sugieren añadir elementos como el ópalo a las carteras.

14th Jul 2019

Existe un tipo de trabajo de diseño conocido como arte del ópalo, que es una artesanía muy compleja que sólo realizan aquellos que son maestros artesanos.

8th May 2018

últimos artículos

Los ópalos negros son la variedad más codiciada, con bases profundas que crean un arcoíris de reflejos en la parte superior. ¡Descubre los usos, las propiedades, la historia y el valor de los ópalos negros!

7th Dec 2025

Descubra cómo se clasifican los ópalos y qué factores influyen en su precio. Desde el color y el brillo hasta la talla y el origen, aprenda cómo se valora cada tipo de ópalo, con ejemplos de rangos de precios.

19th Jul 2023

¡Acompáñanos en un viaje y descubre el poder curativo de los ópalos de la mano de nuestra escritora invitada Vivien Schapera, de Crystal Healing Techniques!

20th May 2023

Categorías de artículos

All there is to know about Opals including Black Opals, Ethiopian Opals & Boulder Opal

14 Artículos

Check out our fascinating information and articles on all things amazing in the Opal world

41 Artículos

Opal Auctions sellers who are approved as opal Verified Sellers

4 Artículos